As the global market for submersible pump technology continues to evolve, understanding the latest trends and innovations is essential for industry professionals and consumers alike. According to a recent report by MarketsandMarkets, the submersible pump market is expected to grow from $8.5 billion in 2020 to $12.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.7%. This growth is driven by increasing industrialization, the demand for efficient water management systems, and advancements in pump design and materials. Additionally, with the emphasis on sustainability and energy efficiency, selecting the right submersible pump requires careful consideration of various factors, including certifications, applications, and operational efficiency. In this blog, we will explore the key trends shaping submersible pump technology in 2025 and provide guidance on how to choose the best option to meet your specific needs.

As we look ahead to 2025, several key innovations in submersible pump technology are set to reshape the industry. One notable advancement is the integration of AI-powered operational intelligence, which enables real-time monitoring and predictive maintenance. This technology not only optimizes pump performance but also reduces downtime, making it an essential tool for any operation dependent on reliable water movement.

Another emerging trend is the focus on sustainable water treatment methods. With increasing environmental awareness, manufacturers are developing pumps that not only conserve energy but also facilitate eco-friendly practices across various applications. Decentralized infrastructure is also gaining traction, allowing for localized water management systems that can be tailored to specific community needs.

Tips for Choosing the Right Submersible Pump: First, consider the specific requirements of your application, including flow rate and head. Next, evaluate the energy efficiency of the pump, as this will impact long-term operating costs. Lastly, assess the reliability of available maintenance support and service options to ensure your investment remains productive for years to come.

When selecting a submersible pump, several key factors must be considered to ensure optimal performance and suitability for your specific needs. First and foremost, the pump's intended application plays a crucial role. According to a report by Global Market Insights, the global submersible pump market is projected to exceed $20 billion by 2025, reflecting a growing demand across multiple sectors, including construction, agriculture, and wastewater management. Understanding your specific application will help determine the appropriate pump size, power, and design to efficiently manage the fluid characteristics involved.

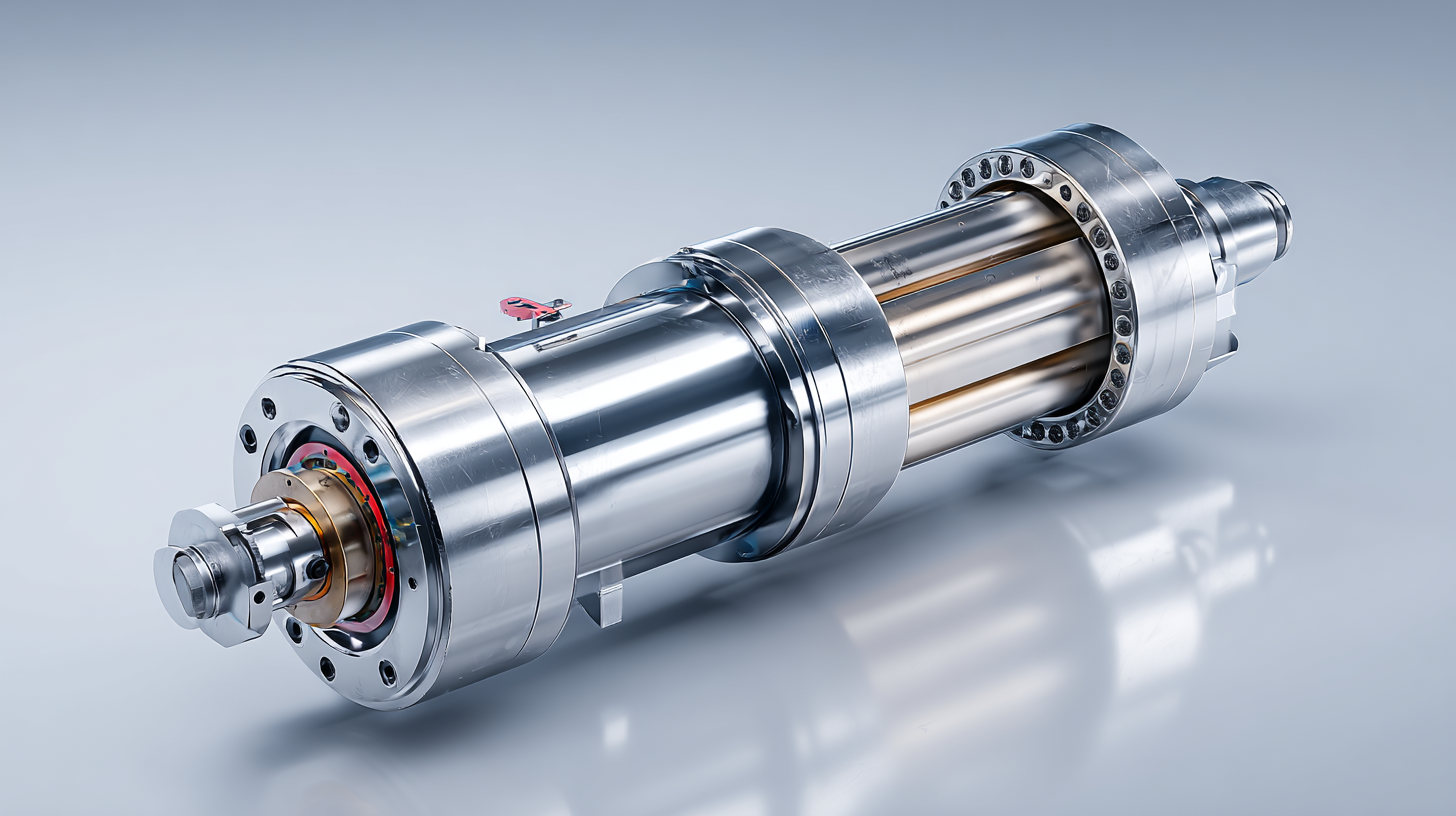

Another vital consideration is the material of the pump. Given the harsh environments in which submersible pumps often operate, selecting a pump made from corrosion-resistant materials is essential. A study conducted by the Hydraulic Institute indicates that pumps composed of stainless steel or specialized polymer materials can significantly enhance durability and longevity, reducing maintenance costs by up to 30%. Additionally, evaluating the horsepower and efficiency rating of the pump will ensure that it meets operational demands without excessive energy consumption, aligning with sustainability goals that are increasingly important in today's market.

When choosing between electric and diesel submersible pumps, performance and efficiency are paramount. Electric submersible pumps are increasingly favored for their lower energy costs and reduced environmental impact. According to a report by the Global Submersible Pump Market Research, electric models can achieve efficiency rates exceeding 90%, making them ideal for continuous operation in applications such as mining and sewage management. They also require less maintenance compared to their diesel counterparts, translating to lower long-term costs.

On the other hand, diesel submersible pumps are known for their robustness and mobility, particularly in remote job sites without reliable electrical access. A study by the World Pumps Association highlights that diesel pumps often provide higher initial flow rates, making them suitable for dewatering applications and emergency scenarios. However, operators must consider the implications of fuel costs and emissions regulations that can arise with diesel models.

**Tip:** When evaluating your options, assess not only the immediate cost but also the operational efficiency and maintenance requirements of each pump type. **Tip:** Ensure that your choice aligns with the specific demands of your project—electric pumps excel in urban and accessible areas, while diesel units may be better for rugged terrains.

This chart compares the performance of Electric and Diesel submersible pumps across four key metrics: Flow Rate (L/min), Efficiency (%), Operating Cost ($/hour), and Maintenance Frequency (times/year). Electric pumps demonstrate higher flow rates and efficiency, while Diesel pumps result in higher operating costs and maintenance requirements.

Maintaining submersible pumps is crucial for enhancing their longevity and operational efficiency. According to a report by the Hydraulic Institute, proper maintenance can extend the operational lifespan of a submersible pump by up to 30%. Regular inspections, including checking seals and bearings, can help identify wear early and prevent costly breakdowns. Additionally, keeping the pump free of debris and ensuring proper lubrication can significantly improve performance. A study published in the Journal of Water Resources emphasizes the importance of routine service schedules, recommending a bi-annual inspection to address potential issues before they escalate.

Maintaining submersible pumps is crucial for enhancing their longevity and operational efficiency. According to a report by the Hydraulic Institute, proper maintenance can extend the operational lifespan of a submersible pump by up to 30%. Regular inspections, including checking seals and bearings, can help identify wear early and prevent costly breakdowns. Additionally, keeping the pump free of debris and ensuring proper lubrication can significantly improve performance. A study published in the Journal of Water Resources emphasizes the importance of routine service schedules, recommending a bi-annual inspection to address potential issues before they escalate.

In choosing the best maintenance practices, users should also consider the specific environment where the pump operates. For instance, submerged pumps in corrosive or sandy environments may require more frequent attention to combat the effects of erosion and corrosion. The American Water Works Association suggests that implementing a preventive maintenance program tailored to the specific conditions can reduce emergency repairs by 40%. This proactive approach not only preserves pump integrity but also enhances reliability in critical applications such as wastewater management and irrigation, ultimately saving time and money in the long run.

As we look ahead to 2025, the trends in submersible pump technology emphasize two pivotal themes: sustainability and efficiency. The global market for peristaltic pumps is projected to grow from $161.75 million in 2025 to approximately $204.53 million by 2032, experiencing a compound annual growth rate (CAGR) of 3.28%. This growth reflects an increasing demand for pumps that promote efficient fluid handling while minimizing environmental impact.

The water treatment equipment market, particularly in the swimming pool sector, is set to witness robust expansion, with predictions estimating market size to rise from $2.5 billion in 2025 to $5.59 billion by 2033. The focus on energy-efficient solutions and sustainable practices is driving innovation in pump designs that align with stricter regulations on energy and emissions. Similarly, advancements in HVAC technology highlight the integration of smart systems, enabling users to manage indoor climates effectively. As industries pivot towards greater sustainability, the adoption of high-efficiency fuel pumps in automotive systems is seen as crucial, responding to environmental policies aimed at reducing carbon footprints.