In the world of manufacturing, Print Inspection Systems are crucial. These systems ensure the quality and accuracy of printed materials. As we head to 2026, the demand for advanced inspection technologies continues to grow.

The effectiveness of Print Inspection Systems directly impacts product integrity. Businesses must evaluate their options. Some systems may not deliver as promised. It’s vital to choose wisely. Low-quality inspections can lead to costly errors.

Many industries rely on print quality. Packaging, labels, and documentation all require precision. However, not all solutions fit every need. It's important to analyze specific requirements and set realistic expectations. This approach will guide better decision-making in selecting the right Print Inspection System.

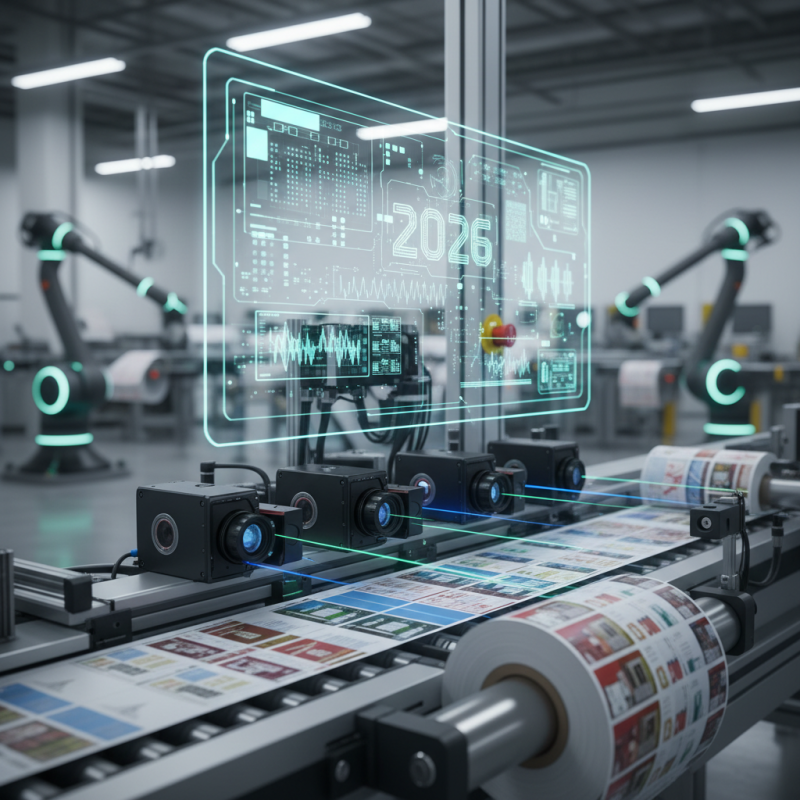

As the printing industry evolves, print inspection systems play a crucial role in maintaining quality. In 2026, these systems are set to integrate advanced technologies like machine vision and artificial intelligence. A recent industry report indicates that the global market for print inspection systems will reach $1.2 billion by 2026. This growth reflects the increasing demand for precision and efficiency in printing processes.

Print inspection systems are designed to detect defects in real time, ensuring high standards for printed materials. A survey shows that 70% of manufacturers believe these systems significantly reduce waste. However, the implementation of such technologies isn't without challenges. Many companies struggle with the initial costs and the learning curve associated with new systems. Training personnel effectively is often overlooked, leading to underutilization.

Moreover, data from industry experts suggests that while 80% of companies invest in these systems, 30% report dissatisfaction due to system inaccuracies. It's essential to continuously refine inspection protocols. Balancing technology adoption and practical application remains a critical endeavor for many in the sector.

In modern print inspection technology, key features can significantly enhance quality control. One essential aspect is the ability to detect ink inconsistencies. A study by Smithers Pira notes that nearly 30% of print defects arise from color variations. This emphasizes the need for systems capable of real-time color analysis. Advanced algorithms now identify inconsistencies that human eyes might overlook.

Another vital feature is the automation of inspection processes. Research shows that automated systems can reduce inspection time by up to 50%. This efficiency not only boosts productivity but also minimizes human error, as tired eyes may miss defects. Adopting automated solutions streamlines operations and increases overall print quality.

Tips:

Regular calibration of your inspection system is crucial. This ensures accurate evaluations. Training staff on system features can also lead to better utilization. Consider integrating feedback loops for continuous improvement in your processes. Inspection isn't just about catching flaws; it's also about enhancing your print's reputation.

As print quality becomes crucial, print inspection systems rise to the forefront. These systems analyze printed material for defects. They help in maintaining high production standards. Accuracy is vital. Some systems excel, but not all. The market offers diverse options that cater to specific needs.

Many leading inspection systems utilize advanced imaging technology. They identify color variations and misalignments swiftly. However, some may struggle with complex backgrounds. Users often report that setup can be challenging. Training staff takes time and effort, which can slow down the process. Some systems might require ongoing calibration, which adds to maintenance costs.

Integration with existing workflows remains a concern. Businesses need systems that work seamlessly. Compatibility issues can lead to inefficiencies. It's essential to consider ease of use without sacrificing performance. Each system has its strengths and weaknesses, making thorough comparisons essential. Understanding these differences can enhance decision-making in selecting the right print inspection system for your needs.

Implementing print inspection solutions in production can greatly enhance quality control. A recent report from a leading industry analyst highlighted that around 10%-15% of printed materials face issues like misalignment or color discrepancies. Such defects can lead to costly reprints or wasted materials.

With advanced print inspection systems, manufacturers can catch these defects early. Automated inspection often results in a 25% increase in productivity. Accurate real-time monitoring allows companies to maintain high standards while reducing human error. However, transitioning to these systems can be challenging. It may require training staff and adapting workflows, which can temporarily disrupt production.

Another key factor is the cost of implementation. While the initial investment can be significant, the long-term savings are evident. A 2022 study found that companies with print inspection solutions reported a 30% reduction in waste over time. Still, not all businesses jump at the chance. Some worry about integration with existing systems or the potential disruption to operational flow.

The print inspection technology landscape is evolving rapidly. Automation and AI are shaping the future. According to recent data from industry experts, 75% of businesses will adopt AI for print quality inspection by 2026. This shift aims to reduce human error and improve accuracy. However, reliance on technology can lead to oversight of nuances that only human inspectors might catch.

Emerging trends indicate a move toward integrating real-time analytics into print inspection systems. Real-time data can enhance decision-making processes significantly. Companies see a potential 30% improvement in production efficiency when using advanced analytics. Yet, the industry still faces challenges. Many systems struggle with adaptability across different print materials and formats.

Sustainability is another crucial factor in innovation. As consumers demand green practices, print inspection technologies must evolve to support eco-friendly processes. Not all solutions are scalable or economically viable. In fact, a significant percentage of firms report difficulties when implementing sustainable inspection technologies. Thus, continuous improvement and reflection on current practices are essential.