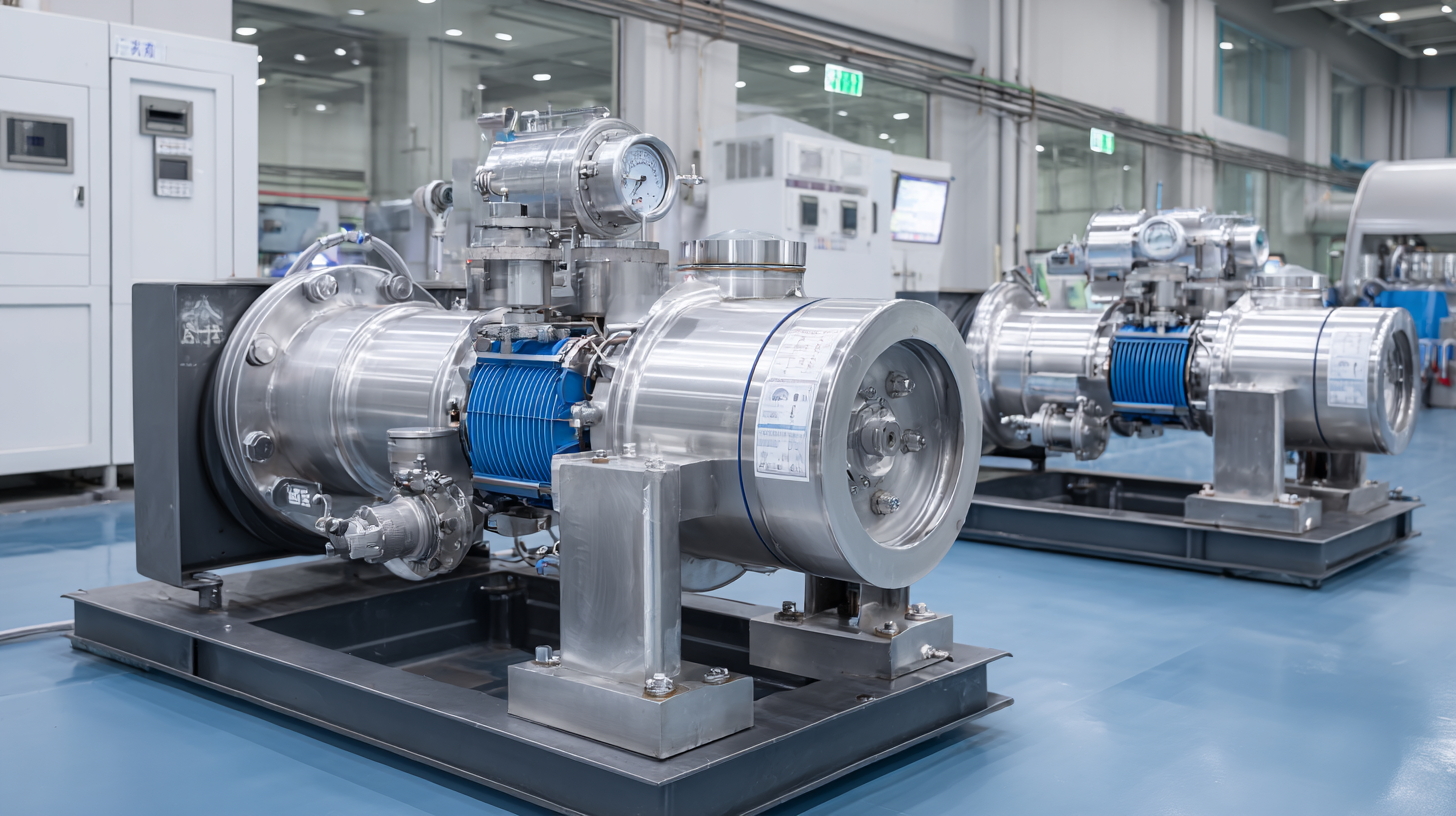

The use of Peristaltic Pumps in industrial applications is gaining significant traction due to their efficiency and versatility in handling a variety of fluids. According to a report by MarketsandMarkets, the global peristaltic pump market is projected to reach USD 1.57 billion by 2026, growing at a CAGR of 6.56% from 2021 to 2026. This growth is largely driven by the increasing demand for precise and reliable fluid transfer in industries such as pharmaceuticals, food and beverage, and water treatment. Peristaltic Pumps offer numerous advantages, including easy maintenance, reduced contamination risk, and the ability to handle corrosive and viscous fluids. As industries continue to prioritize operational efficiency and safety, the adoption of the best Peristaltic Pump technology is becoming a crucial solution for enhancing process control and overall productivity.

Peristaltic pumps have become increasingly vital in various industrial applications due to their unique operational mechanism and benefits. These pumps work by utilizing a rotating mechanism to compress a hose, allowing fluids to be drawn in and subsequently pushed out in a rhythmic motion. This method reduces the risk of contamination and shear stress, making peristaltic pumps ideal for handling delicate fluids such as monoclonal antibodies in low-volume aseptic filling processes. According to industry projections, the peristaltic pumps market is anticipated to reach USD 2.38 billion by 2030, highlighting the growing demand for this technology.

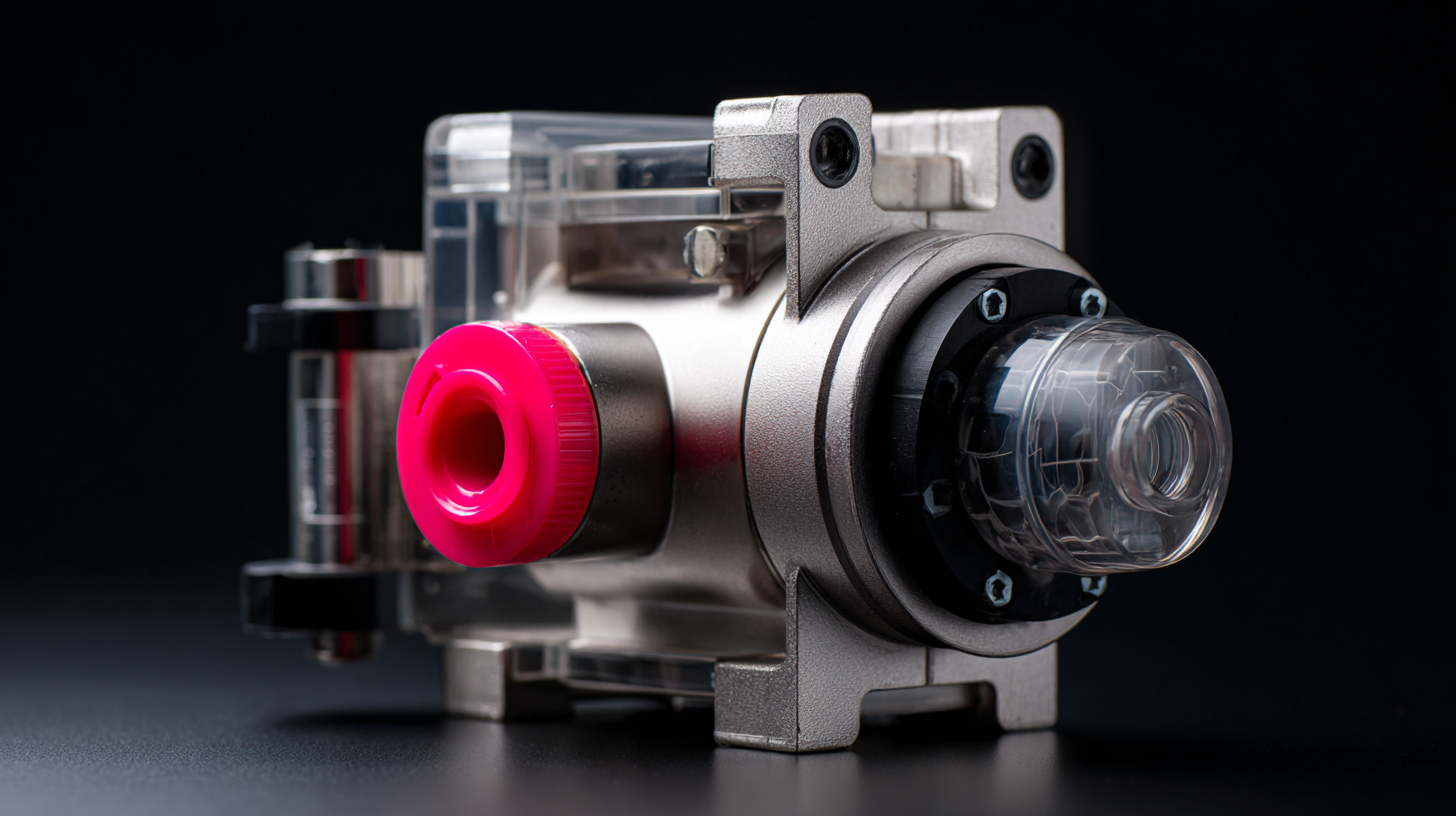

When considering the integration of peristaltic pumps into your operations, it’s essential to focus on the importance of pulsation control. Pulsation can significantly impact microfluidic systems by affecting the flow rates and pressure within the system. Opting for advanced pump technologies that minimize pulsation can enhance the overall efficiency of your processes.

Tips: When selecting a peristaltic pump, ensure that it aligns with your specific fluid handling requirements. Also, explore options with IoT capabilities to improve monitoring and control of pumping systems, which can further boost operational efficiency and sustainability.

When it comes to manufacturing, the advantages of utilizing high-quality peristaltic pumps are manifold. These pumps offer unparalleled precision in fluid transfer, making them ideal for applications that require meticulous dosing of chemicals or other substances. Their design minimizes contamination risks, as fluids are contained within a tube that is only in contact with the fluid, ensuring the integrity of the product being processed. This feature is particularly crucial in biopharmaceutical manufacturing, where strict cleanliness standards are paramount.

Moreover, peristaltic pumps significantly enhance operational efficiency. Their ability to handle a wide range of viscosities and their robust construction enable them to function effectively in harsh industrial environments. This versatility not only reduces the risk of downtime but also allows manufacturers to use fewer pump types across various processes, streamlining operations and reducing inventory costs. As industries continue to adopt advanced technologies, the peristaltic pump market is expected to thrive, making it a smart investment for companies aiming to optimize their manufacturing capabilities.

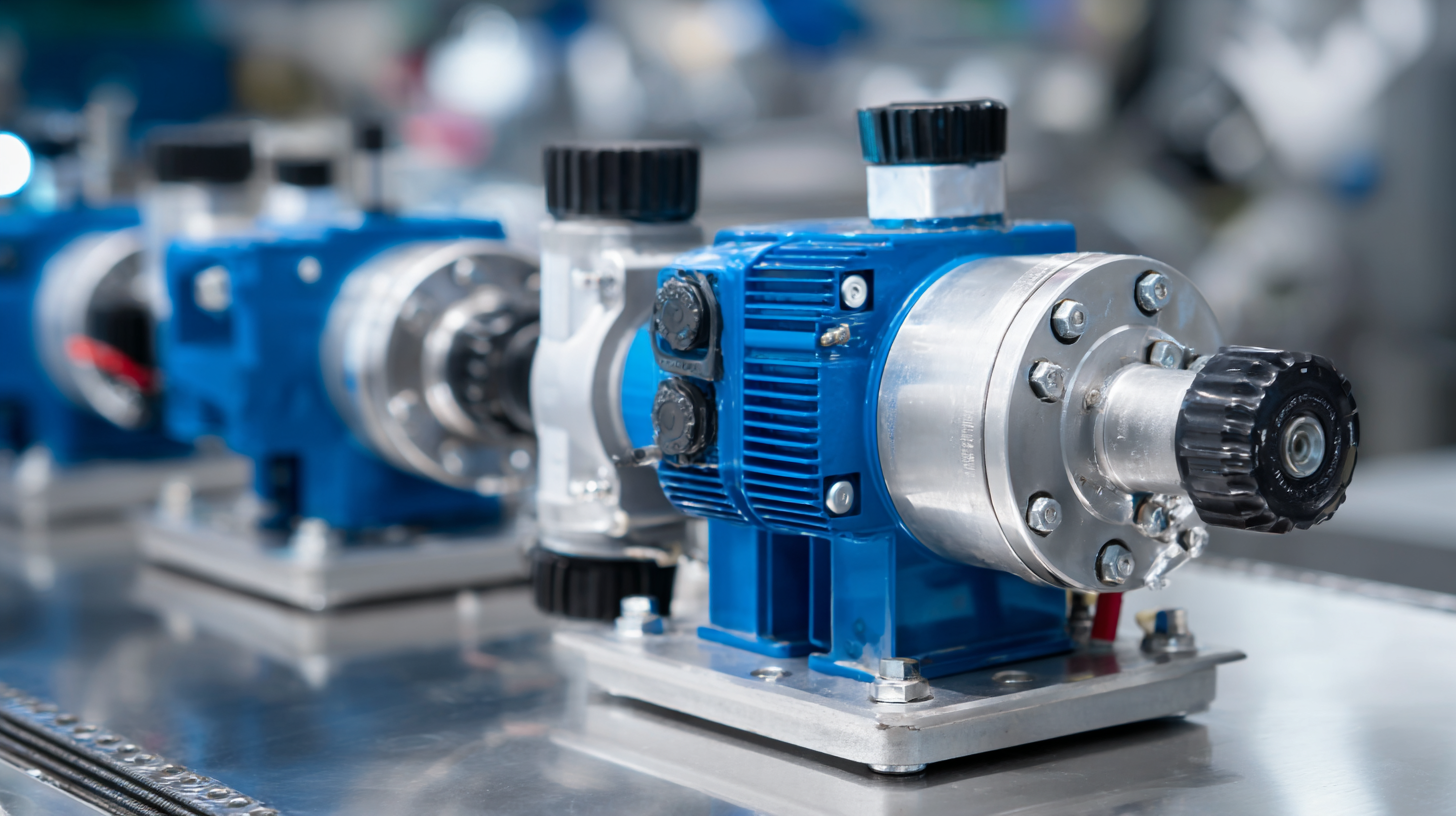

When selecting a reliable peristaltic pump for industrial applications, several essential features must be considered to ensure optimal performance and longevity. First and foremost, the construction material of the pump is critical; it should be robust and resistant to chemical corrosion. This is particularly important in industries where the pump will handle aggressive fluids. Additionally, the ease of maintenance and replacement of tubing can significantly reduce downtime, making it a vital feature for operational efficiency.

Another critical aspect is the flow rate and pressure capabilities of the pump. A versatile peristaltic pump should accommodate a wide range of flow rates to adapt to different operational needs. This versatility allows for gradient gel formation and other specialized applications, making it an invaluable tool across various sectors. Furthermore, the pump's hygienic design is paramount, particularly in food and pharmaceutical industries, where sanitation cannot be compromised. Opting for features like hygienic seals and easy-clean designs can help maintain the integrity of sensitive fluids, ensuring compliance with industry standards.

When selecting a peristaltic pump for industrial applications, identifying a reputable manufacturer is crucial. A reliable manufacturer will not only provide high-quality pumps but also ensure they are at the forefront of technological advancements. For example, the integration of Internet of Things (IoT) and 5G technology is transforming the pump industry, enabling better monitoring, control, and data collection. This means that manufacturers who invest in these innovations can offer products that boost efficiency and reduce downtime.

To identify a reputable manufacturer, consider their experience, customer feedback, and the certifications they hold. A company that demonstrates expertise in precision and reliability, especially in critical uses like hospital infusion systems, is likely to produce more dependable pumps. Furthermore, keeping an eye on trends such as mergers and acquisitions within the pump industry can provide insights into manufacturers that are expanding their capabilities and resources. By focusing on these factors, industrial operators can ensure they select a peristaltic pump from a manufacturer committed to quality and advancement in technology.

| Feature | Advantage | Application Area | Important Factor when Choosing Manufacturer |

|---|---|---|---|

| Accurate Flow Control | Ensures precise dosing and consistency in processes | Pharmaceuticals | Quality Certifications |

| Self-Priming Capability | Allows for easy operation and maintenance | Food Industry | Reputation in the Industry |

| Durability | Long service life reduces downtime | Chemical Processing | Customer Support Services |

| Easy Maintenance | Simplifies the upkeep process | Water Treatment | Product Customization Options |

| Versatility | Can handle a variety of fluids and applications | Environmental Engineering | Technological Innovations |

When considering the purchase of a peristaltic pump for industrial applications, cost plays a pivotal role in the decision-making process. Many businesses might be tempted to opt for cheaper models to save on upfront expenditures. However, this approach often leads to higher long-term costs due to maintenance issues, shorter lifespans, and inefficiencies that can disrupt workflow. Investing in quality peristaltic pumps may indeed require a larger initial investment, but the potential savings from reduced downtime and lower maintenance expenses can significantly outweigh these early costs.

Moreover, high-quality peristaltic pumps offer enhanced reliability and performance, which can be crucial for operations that require precision and consistency. The best pumps are designed to handle various substances, including viscous and abrasive materials, without compromising their functionality. By choosing a top-tier pump, companies can increase their operational efficiency, improve output quality, and ultimately, enhance their profit margins. Thus, while the allure of saving money on lower-cost options might be strong, the long-term benefits of investing in a quality peristaltic pump should not be underestimated.