Choosing the right Aluminum Wire Coating is essential for various applications. Different environments demand different coatings. The right choice protects the wire, extending its lifespan.

Aluminum wire coatings come in many types, each with unique properties. Some are more durable, while others resist corrosion better. Consider the specific needs of your project. Will it face extreme weather? Or will it be used indoors? These questions guide your selection.

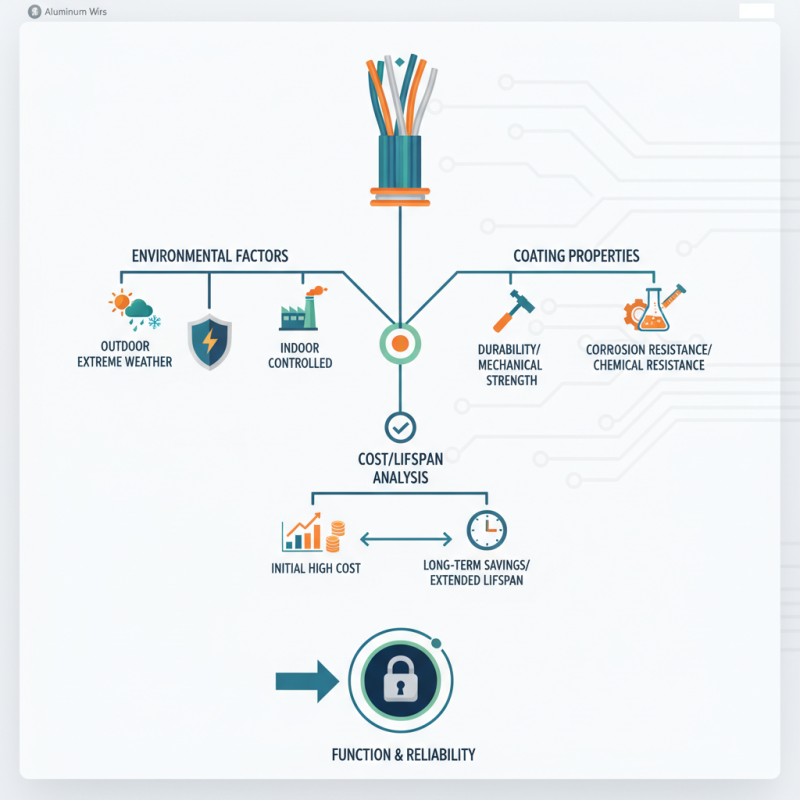

Reflect on the potential downsides. Some coatings may be more expensive upfront. However, they could save money in the long run through durability. Analyze the long-term benefits versus initial costs. This reflection is vital in making an informed decision. Choosing the proper aluminum wire coating is not just about aesthetics; it's about function and reliability.

When choosing aluminum wire coatings, it's crucial to understand the available options. Various coatings provide specific benefits. Some coatings offer enhanced corrosion resistance, while others focus on improving electrical conductivity. A 2022 industry report states that nearly 60% of aluminum wire applications demand high corrosion resistance, especially in marine environments.

Polyurethane, epoxy, and PVC are common coatings. Polyurethane offers excellent wear resistance and flexibility. It can withstand harsh chemicals and varying temperatures. Epoxy coatings, on the other hand, are known for their hardness and durability. They excel in situations where physical damage is a concern. PVC is less expensive but may not provide the same level of protection in extreme conditions.

However, not all coatings perform as expected. While many assume all coatings are equal, variances in thickness and application methods can lead to inconsistent results. A study indicated that up to 20% of aluminum wires fail prematurely due to inadequate or faulty coatings. Regular testing for adhesion and thickness can help mitigate these issues. Understanding these factors will help you make a well-informed decision suitable for your specific requirements.

| Coating Type | Description | Best Use Cases | Advantages | Disadvantages |

|---|---|---|---|---|

| PVC (Polyvinyl Chloride) | A durable plastic coating providing good insulation. | Residential wiring, indoor applications. | Cost-effective, easy to install, good electrical insulation. | Limited UV resistance, can degrade over time in harsh conditions. |

| PE (Polyethylene) | Lightweight coating with reasonable chemical resistance. | Outdoor applications, underground installations. | Good moisture resistance, low cost. | Lower thermal resistance, not suitable for high temperatures. |

| Enameled | A thin varnish layer for a smooth finish and good insulation. | Electronics, transformers, motors. | Excellent insulation properties, compact design. | More expensive, requires careful handling during installation. |

| Thermoplastic | Provides high flexibility and durability with heat resistance. | Automotive, industrial applications. | High melting point, impact-resistant. | Can be more expensive than traditional coatings. |

| Anodized | Electrochemically formed coating that increases corrosion resistance. | Aerospace, marine applications. | Very durable, good for harsh environments. | More costly, irreversible process, can be less conductive compared to other coatings. |

Choosing the right aluminum wire coating involves several key factors. The environment where the wire will be used is crucial. Humidity, temperature, and exposure to chemicals can affect durability. Consider how the coating will perform under specific conditions. For instance, a wet environment may require a more resistant coating.

Another important factor is the wire's intended application. Different uses demand different levels of flexibility and strength. For example, automotive applications often need coatings that can withstand harsh conditions. Look for coatings that offer both protection and functionality tailored to your needs.

Tips: Always check compatibility with existing materials. A poor match can lead to issues down the line. Don’t overlook the cost; cheaper isn’t always better. And remember, sometimes a simple solution is more effective than over-complicating the choice. Testing samples before making a decision can also avoid future problems.

When selecting aluminum wire coatings, understanding the options helps make the right choice. There are several common coatings, each with distinct properties. Polyethylene and PVC coatings, for example, offer good insulation. They protect the wire from moisture and chemicals. These options are budget-friendly but may not withstand extreme temperatures.

In contrast, epoxy coatings provide excellent durability. They resist abrasion and corrosion effectively. However, they can be more expensive. Consider the environment where the wire will be used. In areas with high exposure to chemicals or heat, a robust coating like epoxy might be necessary. Yet, not every project demands the best. Sometimes, a simpler coating suffices for basic tasks.

Reflecting on your specific needs is vital. Think about the longevity you expect. Often, people overlook the importance of compatibility with their electrical systems. Choosing the wrong coating can lead to failure. Making the right decision requires careful consideration and a little research. Each coating has pros and cons, and your choice should align with your project's goals.

Choosing the right aluminum wire coating depends heavily on its intended application. Different coatings offer distinct benefits. For example, polyurethane coatings are excellent for outdoor uses. They provide superior resistance to UV rays and weather. Various installations, like solar panels or telecommunication cables, often benefit from this durability.

Epoxy coatings, on the other hand, are ideal for industrial environments. They offer a robust barrier against chemicals and corrosive elements. Manufacturing plants and factories frequently use this type. However, they may not withstand extreme temperatures as well as others. Users should consider this limitation when selecting the coating.

Another option is PVC coating, known for its flexibility and ease of installation. It’s often used in residential applications like electrical wiring. While it provides good insulation, it may wear down faster in harsh conditions. Evaluating these specifications helps ensure the right choice. Each application has its needs, and one size does not fit all. Reflecting on your specific environment is vital for a successful application.

When it comes to maintaining coated aluminum wires, certain practices can enhance their longevity. Regular inspections can help identify any signs of wear or corrosion. Look for any peeling or cracking in the coating. These small issues can lead to serious problems if not addressed promptly.

Tips for maintaining coated aluminum wires include keeping them clean. Dust and debris can trap moisture against the wire. Use a soft brush or cloth to gently remove buildup. Be cautious not to damage the coating. Moisture and grime can lead to corrosion over time.

It's also wise to keep the wires away from sharp edges or abrasive surfaces. Even small nicks can compromise the coating. If you notice any exposed areas, consider re-coating those sections. Taking these steps can help prolong the life of your aluminum wires, ensuring they stay functional and effective.