When selecting the appropriate condensate pump for your application, it is essential to consider various factors that ensure optimal performance and efficiency. According to the 2021 Market Research Report by Allied Market Research, the global condensate pump market is projected to reach USD 1.89 billion by 2027, growing at a CAGR of 6.2% from 2020 to 2027. This growth highlights the increasing demand for condensate pumps in sectors such as HVAC, industrial processes, and commercial refrigeration. Properly choosing a condensate pump can significantly impact system efficiency and operational costs. Understanding the specific requirements of your application, such as the pump's capacity, head, and features, is crucial in making an informed decision. In this guide, we will explore the essential criteria for selecting a condensate pump that not only meets your operational needs but also contributes to improved sustainability in your systems.

When selecting a condensate pump for HVAC systems, there are several critical factors to consider ensuring optimal performance and reliability. Firstly, understanding the volume of condensate produced is essential. According to the 2022 HVAC Industry Report, systems can produce anywhere from 2 to 10 gallons of condensate per hour, depending on the unit's size and efficiency. Therefore, choosing a pump with a suitable capacity is vital to prevent overflowing and system damage.

Another crucial aspect is the pump's head pressure, which refers to the height the pump must lift the condensate. The same HVAC report indicates that the typical head pressure required ranges from 15 to 25 feet. Choosing a condensate pump with adequate head pressure capabilities ensures efficient drainage, especially in multi-story buildings where condensate must be lifted to higher plumbing levels.

Lastly, consider the pump's materials and durability, particularly in humid environments. Pumps made from corrosion-resistant materials can significantly extend the lifespan of the equipment, reducing maintenance costs. The 2023 Mechanical and Electrical Systems Guide highlights that pumps with high-quality thermoplastic materials outperform standard models by up to 30% in longevity, making them a wise investment for any HVAC system.

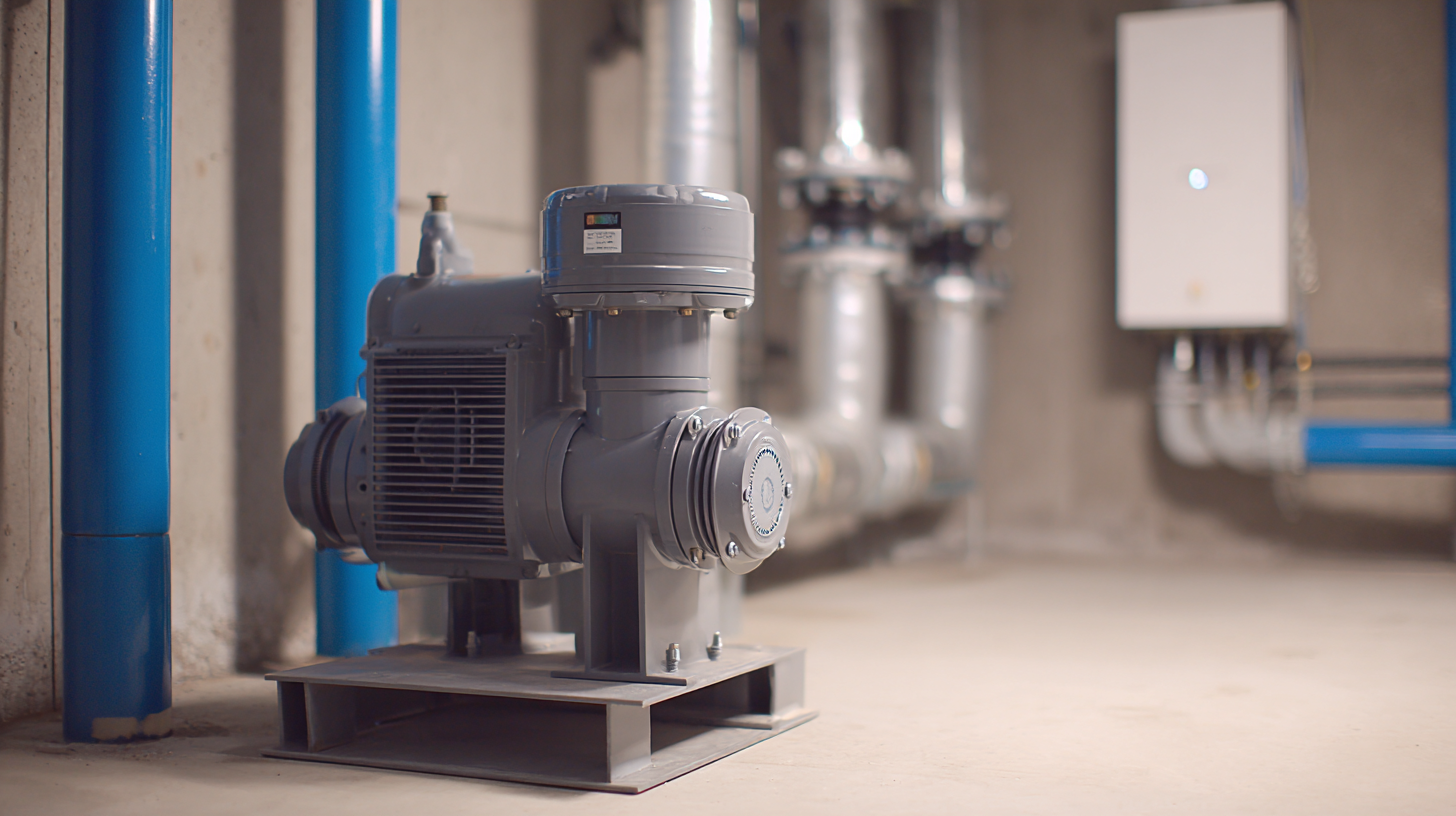

When selecting a condensate pump, understanding the concepts of lift and head is critical to ensuring optimal performance for your specific application. Lift refers to the vertical distance the pump needs to move the condensate from its collection point to the discharge point. This measurement directly affects the pump's efficiency and operational capability. If the lift is underestimated, the pump may struggle to effectively remove condensate, leading to potential system failures or flooding.

Head, on the other hand, encompasses both the vertical lift and any additional friction losses incurred as the condensate travels through piping. This metric not only aids in understanding the pump's capability under varying conditions but also ensures that the pump can handle the nuances of the system, such as bends in the pipe or changes in diameter. Therefore, it is vital to calculate the total dynamic head (TDH) accurately to ensure that the chosen pump can reliably circulate condensate in your system while maintaining the necessary pressure. Proper consideration of lift and head simplifies the selection process and enhances the longevity of the system.

When choosing a condensate pump for your application, it is crucial to evaluate the flow rate requirements for efficient condensate drainage. Different applications demand varying flow rates, depending on the volume of condensate produced and the pumping distance. Understanding the specific needs of your system will help determine the appropriate pump capacity. For instance, industrial settings may require high flow rates due to continuous operation, while smaller residential systems might necessitate lower capacities.

Moreover, it's essential to consider the potential impacts of pump selection on overall system efficiency. For example, an oversized pump can lead to energy waste, while an undersized one may cause frequent cycling and premature failure. By analyzing the flow rate needs and ensuring that the chosen pump aligns with those requirements, you can improve not only the efficiency of the condensate drainage but also enhance the sustainability of your operation in the context of rising energy costs and environmental concerns.

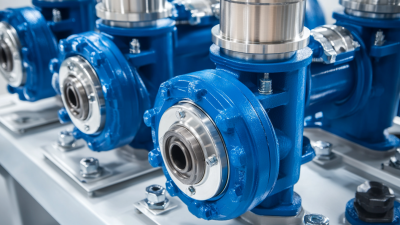

When selecting a condensate pump, focusing on key specifications such as material and durability is essential for ensuring long-term performance. Pumps made from corrosion-resistant materials, like stainless steel or thermoplastic, tend to have a longer lifespan. According to industry reports, pumps constructed with high-quality materials can reduce maintenance costs by up to 30% over their operational life. In applications where the condensate may contain aggressive chemicals or high temperatures, investing in a high-durability pump will pay off significantly.

Moreover, the durability of the pump should be assessed in the context of its application. For example, a pump used in continuous operation scenarios must withstand higher wear and tear compared to those used intermittently. Research indicates that pumps designed for high-pressure environments show a 25% increase in reliability when featuring reinforced components. By prioritizing material quality and assessing operational demands, users can select a condensate pump that not only meets their immediate needs but also ensures efficient and hassle-free operation in the long run.

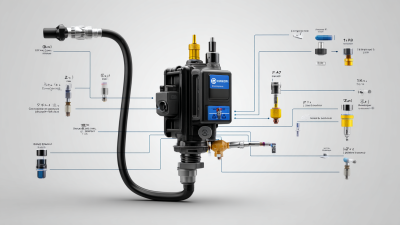

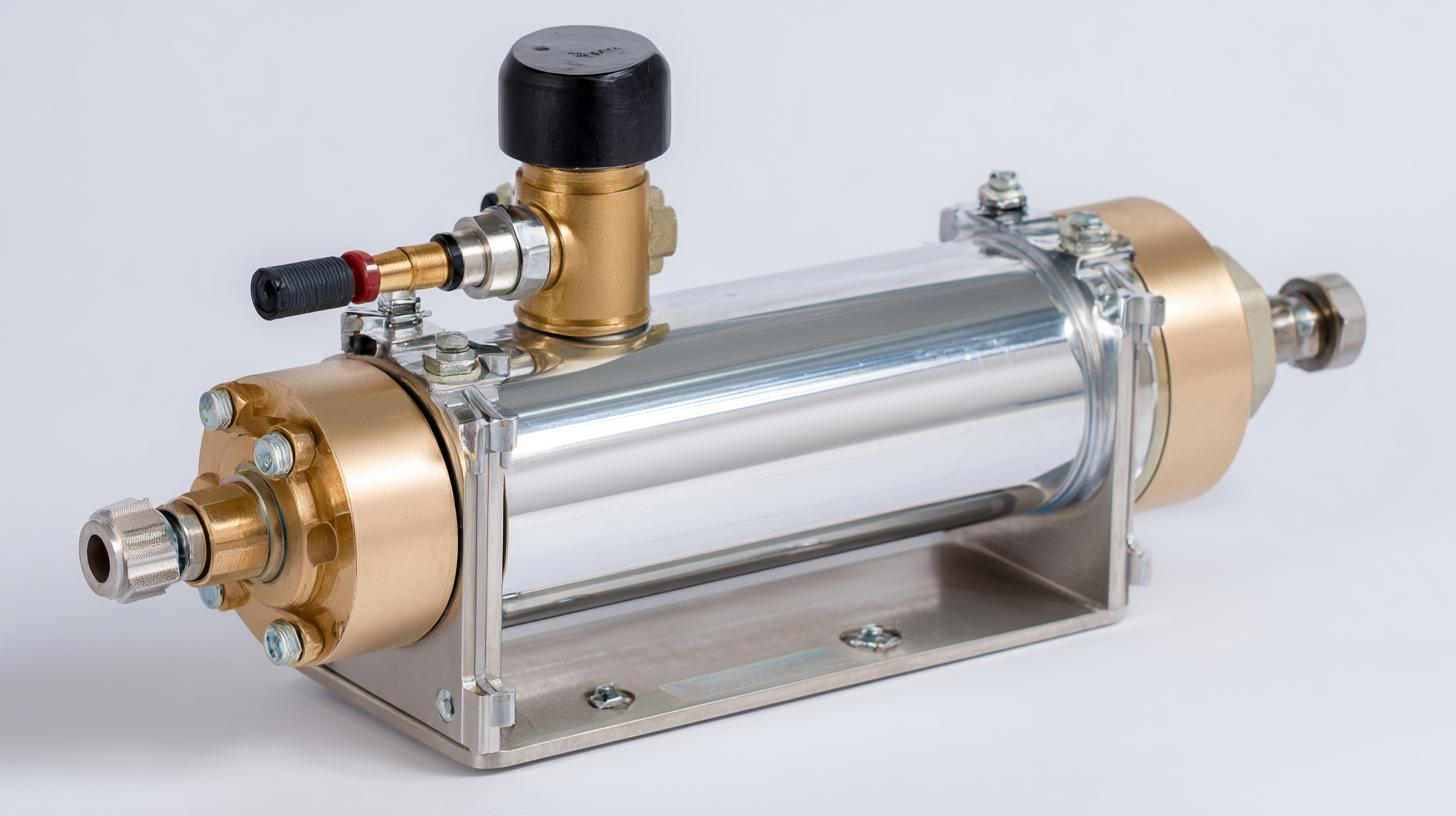

When selecting a condensate pump for your application, understanding the power options available is crucial. Two primary types of power sources for condensate pumps are electric and pneumatic systems.

Electric condensate pumps are often favored for their efficiency and lower operating costs. They utilize synchronous motors, where the speed in revolutions per minute (rpm) is directly influenced by the alternating current (AC) frequency and the number of poles in the motor. This makes them suitable for various industrial applications due to their ability to maintain consistent performance under variable loads.

On the other hand, pneumatic condensate pumps leverage compressed air, making them beneficial in environments where electrical sources are limited or where potential hazards exist due to flammable materials. These pumps are known for their durability in harsh conditions and can handle high-pressure applications. As industries continue to evolve in their practices, understanding the specific benefits of each power option is essential for achieving optimal performance and reliability in condensate management systems. Such insights can enhance the efficiency of operations, particularly in facilities like landfills, where proper gas collection and maintenance are vital.