Fluid management is a critical aspect across various industries, from agriculture to oil and gas, impacting operational efficiency and sustainability. With the global transfer pump market projected to reach $5.54 billion by 2026, the demand for innovative solutions has never been higher. Transfer pumps play a pivotal role in the smooth transportation of liquids, minimizing waste and optimizing workflow. Recent advancements in technology have led to the development of more efficient and reliable transfer pump systems, capable of handling a wider range of fluids and environmental conditions. As industry professionals seek to enhance their fluid management strategies, understanding the latest innovations in transfer pump technology can lead to significant improvements in performance and cost-effectiveness. In this blog, we'll explore how to select the best transfer pump solutions and leverage cutting-edge innovations to maximize efficiency in fluid management.

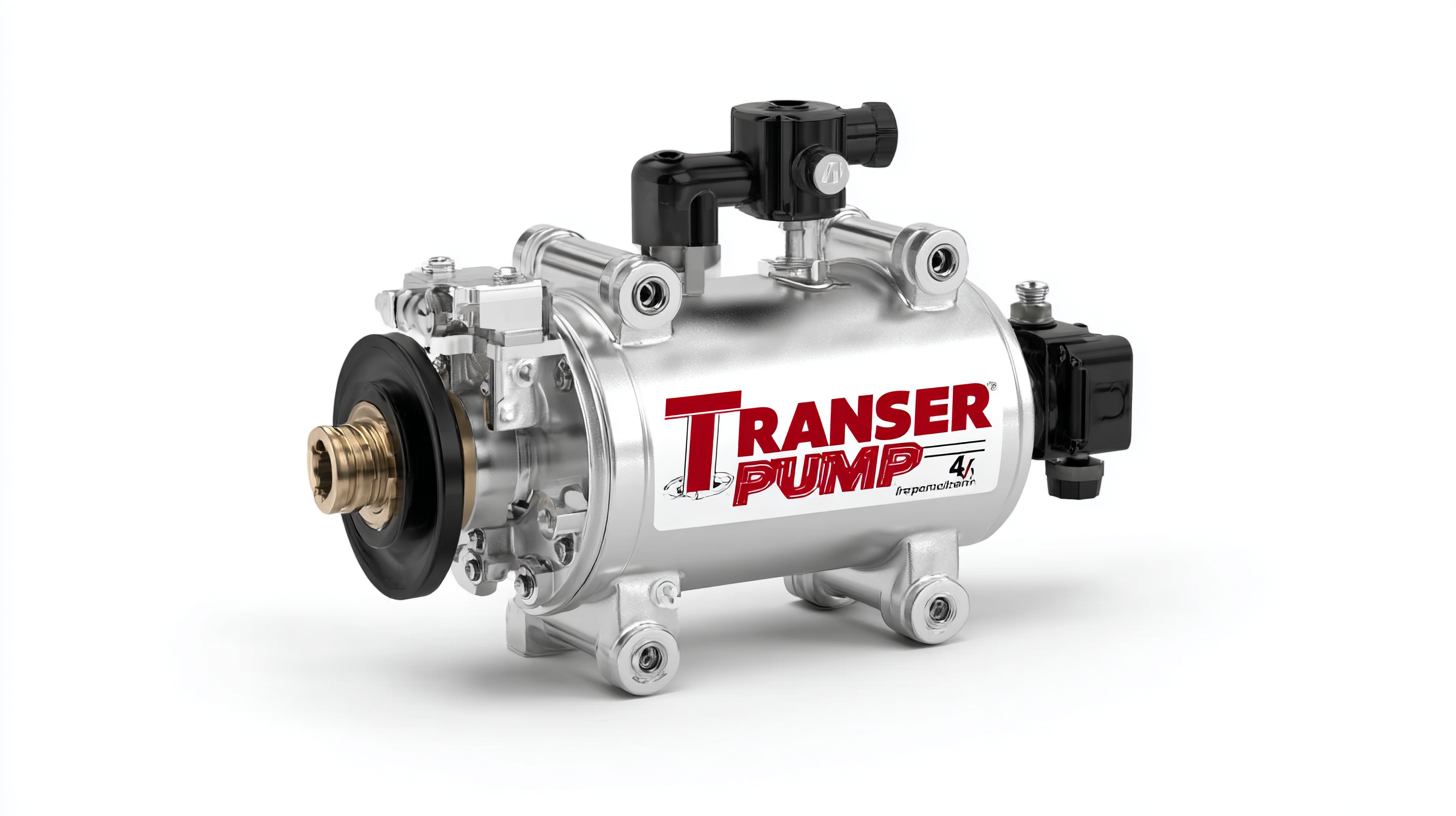

In the world of heavy-duty fluid management, innovative transfer pump technologies have emerged as crucial tools for maximizing efficiency and reliability. These advanced pumps are designed to handle various fluids safely and effectively, providing enhanced performance in challenging environments. With features like variable speed settings and energy-efficient designs, modern transfer pumps can adapt to the needs of any application, ensuring smooth operations across industries such as construction, agriculture, and manufacturing.

Tips: When selecting a transfer pump, consider the specific fluid type and viscosity, as this will affect pump performance. It's also vital to assess the required flow rate and discharge pressure to ensure the pump meets your operational needs. Regular maintenance is another key aspect; implementing a routine check on seals, filters, and hoses can prolong the life of your equipment and prevent costly downtime.

Moreover, many of the latest transfer pumps are equipped with smart technology for real-time monitoring and control. This innovation not only optimizes performance but also enhances safety by reducing the risk of overflows or leaks. Investing in these features can lead to significant long-term savings, making them an attractive option for businesses focused on efficiency and sustainability.

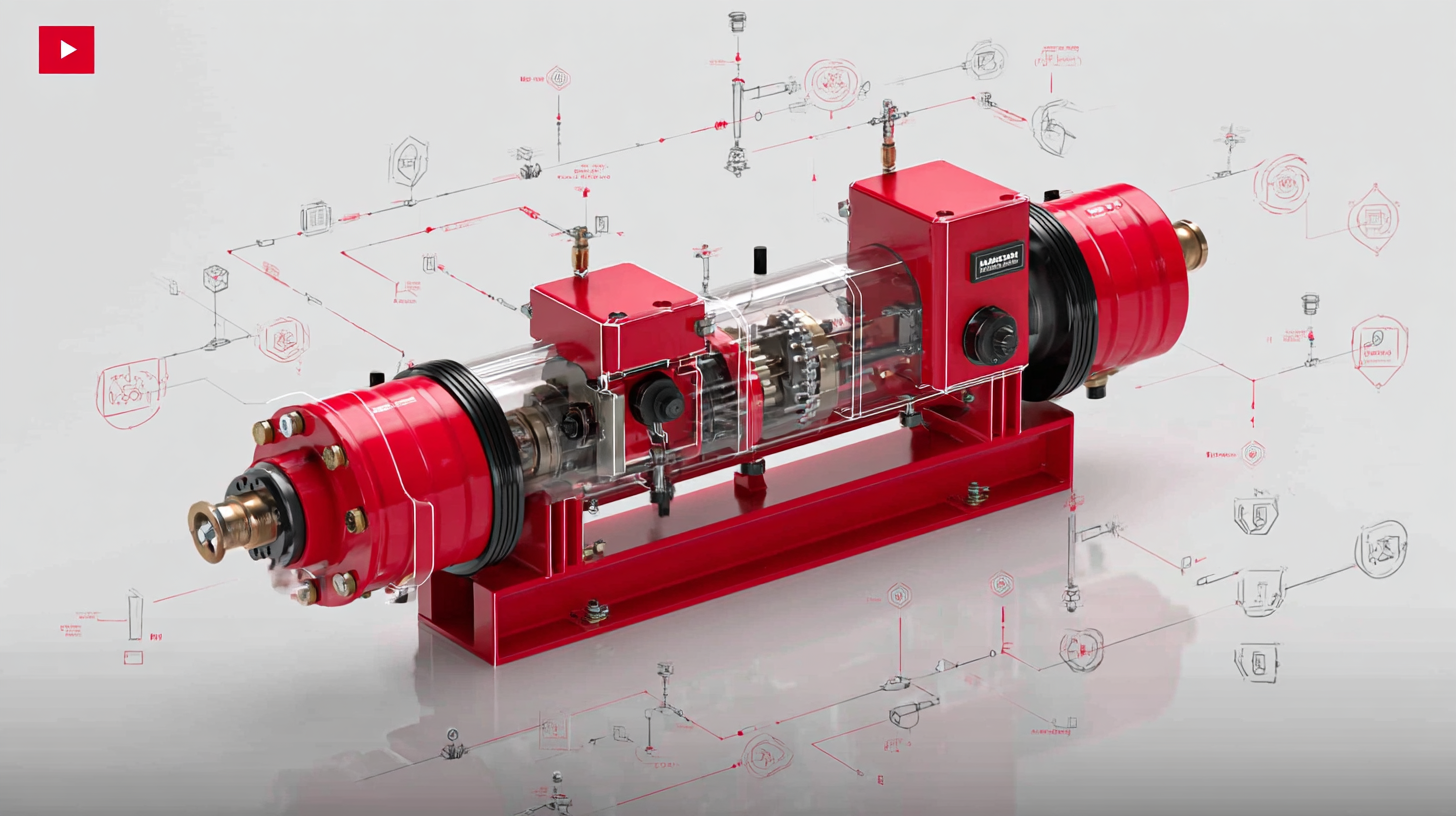

When it comes to fluid management, the choice between centrifugal and positive displacement pumps is critical to achieving efficiency. Centrifugal pumps, which operate on the principle of converting rotational energy into fluid movement, are ideal for large volume transfers of low-viscosity fluids. According to a 2021 industry study, centrifugal pumps account for approximately 80% of the market in municipal water supply systems due to their ability to handle a wide range of flow rates and pressures with relatively low energy consumption.

On the other hand, positive displacement pumps excel in applications requiring precise flow control and consistent pressure, making them suitable for high-viscosity fluids or applications needing high suction power. A report from the American Society of Mechanical Engineers noted that positive displacement pumps can deliver up to 95% efficiency in certain conditions. This efficiency is particularly important in industrial settings where the cost of downtime and energy use can be significant, emphasizing the importance of selecting the right pump type based on the specific requirements of the fluid being managed.

In an era where sustainable solutions are gaining traction, solar-powered pumping systems are revolutionizing the fluid transfer landscape. These innovative pumps harness the energy of the sun to efficiently move liquids, drastically reducing dependence on traditional fossil fuels. With their environmentally friendly design, solar-powered pumps cater to a variety of applications, from agricultural irrigation to water supply in remote areas. This not only helps in cutting operational costs but also enhances access to clean water, promoting sustainability and resilience in communities worldwide.

Moreover, advancements in solar technology have led to significant improvements in the efficiency and reliability of these pumping solutions. Modern solar-powered pumps are equipped with intelligent control systems that optimize energy consumption and ensure consistent performance, even in fluctuating weather conditions. This adaptability makes them particularly valuable in regions where access to electricity is limited or unreliable. By integrating solar energy into fluid management systems, businesses and individuals alike can contribute to a greener future while enjoying the economic benefits of reduced energy costs and maintenance requirements.

When evaluating transfer pumps, robustness and reliability are paramount for ensuring efficient fluid management across industries. According to a report by the Hydraulic Institute, nearly 30% of operational failures in fluid systems can be attributed to pump inefficiencies or malfunctions. These statistics underscore the necessity for manufacturers to adhere to stringent industry standards such as ISO 9906 for hydraulic performance and API 610 for clean liquids handling. Ensuring compliance not only enhances performance but also extends the lifespan of the equipment.

**Tip:** When selecting a transfer pump, always check for performance curves provided by manufacturers. This will allow you to assess the pump’s efficiency under various operating conditions, helping you make an informed decision based on your specific fluid handling requirements.

In addition to performance standards, robust construction plays a crucial role in pump reliability. Materials used in pump manufacturing, such as corrosion-resistant alloys, significantly influence durability when dealing with aggressive fluids. The American National Standards Institute (ANSI) sets guidelines that can help buyers distinguish pumps capable of withstanding harsh environments.

**Tip:** Consider the total cost of ownership (TCO) by looking beyond the initial purchase price. Evaluating maintenance needs, downtime risk, and energy efficiency can lead to better investment choices in the long run.

The fluid management industry is undergoing a significant transformation as technology advances, particularly with the integration of smart pumps and IoT. This trend is not only enhancing operational efficiency but also offering unprecedented control over fluid management systems. By 2024, the household water pump market is projected to be valued at $18.58 billion, with a remarkable increase to $26.92 billion by 2032, highlighting the growing demand for innovative solutions in fluid transfer.

One of the most effective strategies to improve efficiency is implementing smart pumps that can communicate data in real-time. These advanced pumps not only optimize energy usage but also reduce maintenance costs through predictive analytics. Tips for selecting the right smart pump include considering your specific fluid management needs, evaluating energy efficiency ratings, and ensuring compatibility with existing systems for seamless integration.

Moreover, IoT-based solutions allow for remote monitoring and control of pump operations, significantly improving responsiveness to changing demands. Users should invest in systems that provide intuitive interfaces and robust data analytics to maximize their operational insights. For optimal efficiency, regular maintenance checks and timely software updates are crucial to keep the system running smoothly. Embracing these future trends will undoubtedly lead to more efficient and sustainable fluid management practices.

| Pump Type | Flow Rate (L/min) | Power Source | IoT Capability | Smart Features |

|---|---|---|---|---|

| Submersible Pump | 150 | Electric | Yes | Remote Monitoring |

| Diaphragm Pump | 80 | Pneumatic | No | Leak Detection |

| Centrifugal Pump | 200 | Electric | Yes | Flow Rate Monitoring |

| Gear Pump | 60 | Electric | No | Pressure Monitoring |

| Peristaltic Pump | 120 | Electric | Yes | Self-Priming Feature |