In today's fast-paced world, the demand for efficient and versatile equipment has never been greater, with portable pumps emerging as essential tools across various industries. From construction sites to agricultural applications, these compact devices provide unmatched convenience and flexibility, ensuring that tasks can be executed swiftly and effectively wherever needed. However, with the plethora of options available globally, sourcing the best portable pumps can be a daunting task for businesses aiming to meet their specific needs.

To navigate the complexities of the portable pump market, it is crucial to identify key factors that influence performance, reliability, and cost-effectiveness. Understanding the various types of pumps, their applications, and the latest technological advancements will empower buyers to make informed decisions. This blog aims to provide essential insights and best practices for sourcing the most suitable portable pumps, ensuring that you invest in equipment that aligns with your operational requirements and enhances productivity. Whether you are looking for a pump for emergency dewatering or fluid transfer, our guide will help streamline your selection process and connect you with the right solutions globally.

When choosing portable pumps, several key factors must be considered to ensure you select the best option for your specific needs. According to a recent report from Research and Markets, the global portable pump market is expected to grow significantly, with an estimated CAGR of over 5% from 2022 to 2028. This uptick in demand underscores the importance of making informed purchasing decisions based on essential insights. One of the primary considerations when sourcing portable pumps is the application type. Different industries, such as construction, agriculture, and emergency response, require pumps with varying capabilities and specifications. For example, the American National Standards Institute (ANSI) highlights that pumps used in construction often need to handle high solid content, while pumps for agricultural use might focus more on efficiency and durability. Understanding the specific requirements of your industry can help narrow down the options significantly. Another crucial factor is the pump's power source. Portable pumps can be gasoline, diesel, or electric-powered, each coming with distinct advantages and disadvantages. According to a report by MarketWatch, electric portable pumps are gaining traction due to their lower operational costs and environmental benefits. However, in remote locations where electricity is unavailable, gasoline or diesel pumps might be the only feasible options. Evaluating the accessibility of power sources in your operational area is essential for optimal performance. Lastly, the build quality and portability of the pump should not be overlooked. A robust design ensures longevity and reliability, especially in demanding environments. The European Pump Manufacturers Association (EPMA) reports that weight and ease of transportation are critical factors for those frequently moving pumps. Lightweight materials combined with ergonomic features can enhance mobility, making it easier to deploy the pump when and where it's needed. Keeping these elements in mind will help in selecting a portable pump that fits your operational demands efficiently.

When evaluating portable pumps, understanding their performance metrics is crucial to sourcing the best option for diverse applications. Metrics such as flow rate, pressure capacity, and energy efficiency play significant roles in determining the suitability of a portable pump. According to industry reports, pumps that achieve a consistent flow rate of at least 4 liters per minute tend to be favored in industrial settings. An efficient pump should not only maintain this flow rate but also provide reliability under varying operational conditions.

Recent developments in pump technology mirror advancements in other portable devices, akin to trends seen in fitness trackers that measure vital metrics like steps and calories burned. Just as these devices aim for a balance between functionality and portability, portable pumps are increasingly designed to be lightweight while maximizing performance. A notable comparison in the industry highlights the efficacy of high-performance liquid chromatography (HPLC) pumps, which require precise calibration methods to ensure optimal flow rates and performance metrics, demonstrating that advanced technology significantly enhances operational accuracy.

Moreover, energy consumption has become a focal point for many consumers. Reports indicate that modern portable pumps with energy-efficient designs can reduce energy expenditure by up to 30% compared to older models. This emphasizes the importance of evaluating a pump's performance metrics not just from a functionality standpoint, but also in terms of sustainability. As more industries turn to portable solutions, targeting pumps that balance performance, efficiency, and reliability becomes essential for successful outcomes in various applications.

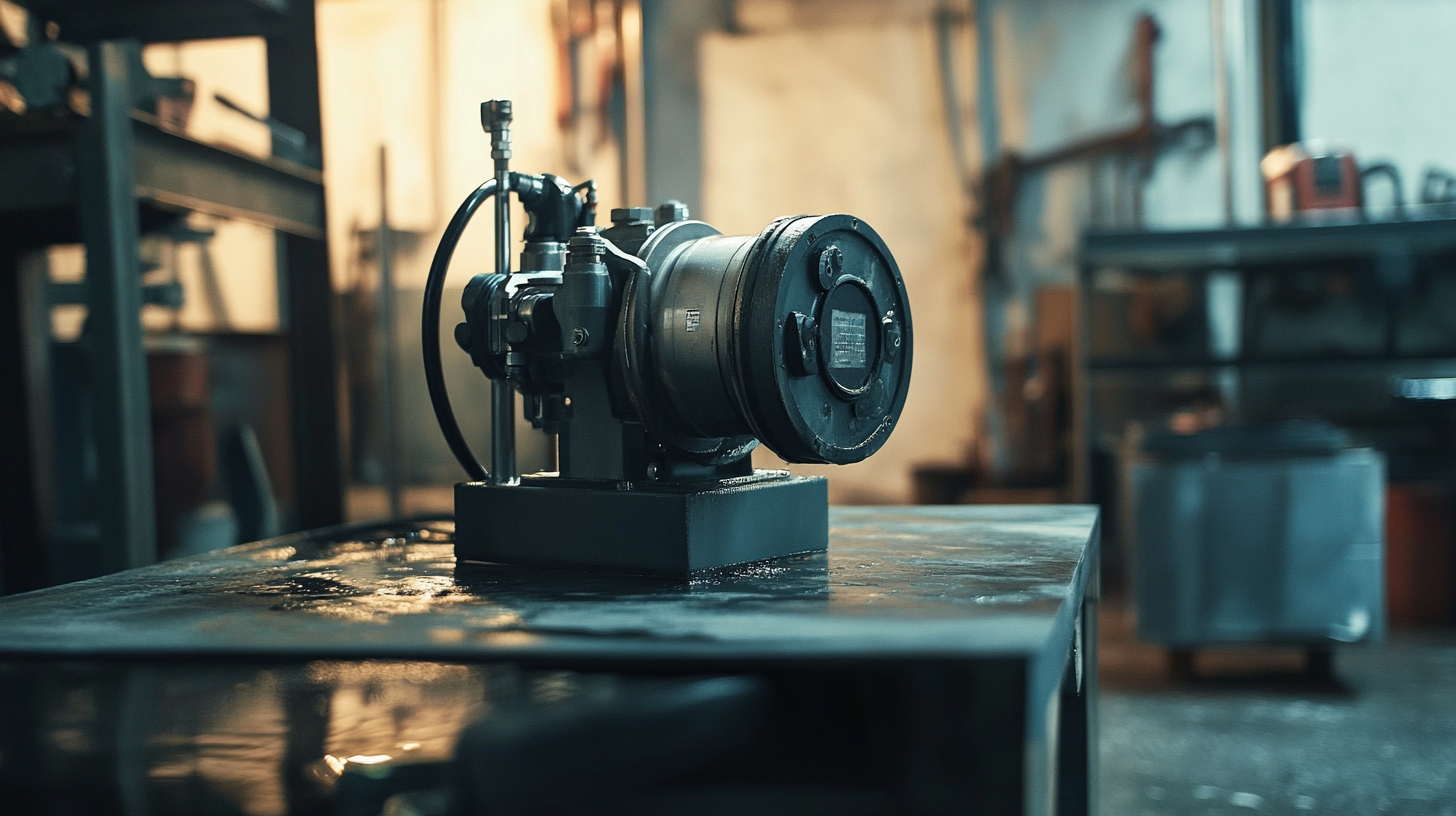

When it comes to sourcing the best portable pumps globally, understanding the various types available is crucial. Portable pumps can be broadly categorized into several types depending on their application and design. The most common types include diaphragm pumps, centrifugal pumps, and submersible pumps, each offering unique benefits and functionalities.

Diaphragm pumps are renowned for their versatility and ability to handle a wide range of liquids, including abrasive and viscous fluids. They operate using a flexible diaphragm that creates a vacuum to draw in the fluid, making them an excellent choice for industries such as chemical processing and water treatment. Their ability to run dry without damage adds to their appeal, especially in rugged environments where reliability is a must.

Centrifugal pumps, on the other hand, are designed for high flow rates and are widely used in applications where speed is essential. Their operation is based on the principle of centrifugal force, which propels liquids efficiently through the system. These pumps are ideal for agricultural, construction, and industrial applications where quick drainage or liquid transfer is required. However, they may struggle with thicker liquids or those with suspended solids, so careful consideration of the application is necessary.

Submersible pumps, as the name suggests, are designed to operate while submerged in the fluid they're pumping. They are often used in applications like dewatering, groundwater removal, and sewage pumping. The seal design helps prevent leaks and electrical hazards, making them a safe choice for many settings. Understanding these differences can greatly aid in selecting the right portable pump for specific needs, ensuring efficiency and reliability in any operation.

When sourcing the best portable pumps globally, reliability and durability in design should be at the forefront of decision-making. The portable pump market, much like the rapidly evolving portable desk fan industry, demands products that can withstand varied conditions while maintaining efficient performance. With increasing consumer expectations, assessing the materials and construction of portable pumps is crucial. High-quality, corrosion-resistant materials can significantly extend a pump's lifespan, making them ideal for both domestic and industrial applications.

Additionally, the market is seeing a push for versatility, reflecting trends in products such as USB-powered and battery-operated fans. Consumers desire pumps that are not only portable but also adaptable to different power sources and operational needs. A well-designed portable pump should integrate smart technology to enhance user experience, ensure ease of use, and provide reliable performance irrespective of the environment. As manufacturers respond to these demands, innovations in pump designs must also focus on energy efficiency and sustainability, mirroring broader trends across various consumer-driven markets.

As we anticipate upcoming developments in portable pumps, keeping an eye on competitive assessments and product forecasts will be essential. Just as the most efficient dehumidifiers of 2025 showcase advancements in technology and energy consumption, the leading portable pumps of tomorrow will likely prioritize performance, reliability, and user convenience, setting new standards in the industry.

When sourcing portable pumps on a global scale, understanding the landscape of suppliers is crucial to achieving competitive pricing while maintaining quality. A recent report from MarketsandMarkets predicts that the global portable pump market will grow from USD 4.5 billion in 2022 to USD 6.9 billion by 2027, reflecting a CAGR of 8.8%. This growth is driven by increasing demand across industries such as construction, agriculture, and wastewater management. Therefore, identifying the right suppliers who offer a balance of cost-effectiveness and high-quality products is essential.

Navigating the vast array of global suppliers can be daunting, but focusing on key regions known for their manufacturing strengths can yield better results. According to a study by ResearchAndMarkets, Asia Pacific holds over 40% of the market share in portable pump manufacturing, with China and India emerging as significant players. This region not only offers competitive prices but also has steadily improved its quality standards, making it an attractive choice for businesses looking to optimize their sourcing strategies. Partnering with vetted suppliers from these areas can lead to sourcing pumps that meet stringent quality benchmarks without inflating costs.

Moreover, consistency in product quality is paramount. A report by IBISWorld highlights that 20% of businesses in the pump industry cite quality assurance as a top challenge. To mitigate this risk, companies should consider engaging in direct audits and quality control inspections before finalizing contracts. Leveraging technology, including platforms for real-time supplier evaluation, can also facilitate the selection process, ensuring buyers connect with suppliers who uphold a commitment to both competitive pricing and product excellence.